Hey folks ! I'm the big cheese over at 하나기술, and our gig is all about crafting the nifty machinery needed for secondary cell production. Let's dive right into the nitty-gritty of how secondary cells are whipped up and how our gear plays a crucial role in the manufacturing mix.

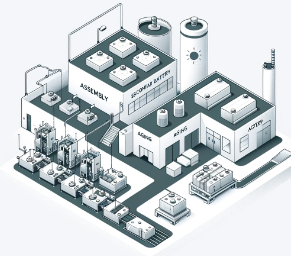

So, first things first, let's get the lowdown on how secondary cells are cooked up. We can break it down into four simple steps : Electrode, Assembly, Electrochemical Reactions, and Final Packaging. Just a heads-up, we've got your back on three of these steps, but the Electrode process is a different ballgame.

Now, let's keep it simple and focus on the trio of steops we're all about. First up, Assembly. The Electrode process? Well, it basically cranks out the 'electrode' stuff, like anodes and cathodes. We then roll up our sleeves and get busy putting it all together with seperators to shape up those secondary cells. There are two ways to do this, but we won't get bogged down in those details - just remember we can wind or stack'em.

Next on the docket is the Electrochemical Reactions bit. Don't let the fancy name throw you off; it's just about charging and discharging the cells to make sure they're working like a charm. After that, we let them age gracefully in storage, hoping they pick up all the right features along the way. Once they've matured a bit, we give'em a little something called degassing to make sure there's no pesky leftover gas inside. Almost there!

Last but not least, let's talk about packing and testing. We wrap these babies up to fit snugly into various applications like Evs, heavy machinery, ESS, and more. But hey, we're not done yet - gotta run some tests to ensure top-notch quality. You never know, during the packaging process, a hiccup might sneak in.

Our game plan is all about making life easy for our clients. We're here to take the worry out of handling all these processes. We've got the whole turn-key solution vibe going on, so why wouldn't you want to partner up with us ?

Hello, guys! I’m the head honcho over at 하나기술. We are all about making necessary machineries for secondary cells. Let's break down how secondary cells are made and what our machineries do in the manufacturing process.

You should know how secondary cells are made, first. The processese can come in four parts - Electrode, Assembly, Electrochemical reactions, Final packaging. We can provide our clients with three of them, except Electrode process. Then, it will be easy if we focus on the rest three parts, right? Ok, let's get into them. First, Assembly. The Electrode process literally produces 'electrode', such as anode, cathode. Then, we can assemble them with seperators to shape the secondary cell. There are two types for assembling, but we're not gonna talk about them. Just remember those are the ways of winding, stacking.

The next step is Electrochemical reactions. Don't fret for the long name of it. It is just to keep charging and discharging the cell to see if it works well. After it, we age it in a storage, praying they would adopt the necessary features as the cell. After aging, we should do a process called degassing to take out gas that might be left in the cell. We're almost done. The last step is packing and testing. We package them to fit into shapes for applications like EVs, heavy machineries, ESS, and more. And, do not forget to test them. While we package them, it might has some problems. So, we test them after packaging to make sure for the quality.

Our business strategy is to make our clients not get into any worries to adopt all processes. We can give them turn-key solution for making secondary cells. Isn't there a reason they don't work with us ?